Hardfacing

We are an unparalleled biopharmaceutical company.

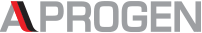

Thermal Spray

Thermal Spray is a surface treatment technology that improves performance and lifetime of parts by using high temperature flame to coat those parts with special materials having abrasion resistance, corrosion resistance, heat resistance and insulation resistance.

Compared to the previous Overlay Welding, this coating technology enables treatment of functional film without giving thermal effect to parts, and its application is extended to such industries as steel, paper manufacture, petrochemistry and power plant.

Compared to the previous Overlay Welding, this coating technology enables treatment of functional film without giving thermal effect to parts, and its application is extended to such industries as steel, paper manufacture, petrochemistry and power plant.

Technology in possession

High Velocity Thermal Spray (HVOF, High Velocity Oxy-Fuel), Plasma Thermal Spray (Plasma Spray), Self-Fluxing Alloy Thermal Spray(SFA)

Applications

Steelworks: Sink roll, Hearth roll, Support roll, Process roll etc.

Petrochemistry: Piston/pump rod, Valve, Impeller etc.

Power Plant: Impeller, Bucket, Blade, Valve Flange etc.

Paper Manufacture: Expander roll, Doctor blade, Corrugated roll etc.

Textile: Grove roll, Spindle disc, Feed roll, Jacket roll etc.

Petrochemistry: Piston/pump rod, Valve, Impeller etc.

Power Plant: Impeller, Bucket, Blade, Valve Flange etc.

Paper Manufacture: Expander roll, Doctor blade, Corrugated roll etc.

Textile: Grove roll, Spindle disc, Feed roll, Jacket roll etc.

Cold Spray

Cold Spray is a surface treatment technology that improves performance and lifetime of parts by spraying and stacking in high speed the high conductive, corrosion resistant and chemical-resistant material on the surface of the parts without melting. In particular, this is one of the Additive Manufacturing (AM) technologies, such as 3D printing which is called the 3rd industrial revolution and is being extended to such industries as aerospace, nuclear power and defense industry.

Technology in possession

Cold Gas Spray, Warm Spray

Applications

- Spent nuclear fuel disposing vessel and nuclear fuel cladding pipe surface treatment

- Difficult-to-cut materials additive processing and parts manufacturing (3D printing parts)

- Corrosion-resistant coating and repair of Al-family alloy parts in airplanes or transporting machines

- Conductive pattern applied metal/ceramic parts

- Difficult-to-cut materials additive processing and parts manufacturing (3D printing parts)

- Corrosion-resistant coating and repair of Al-family alloy parts in airplanes or transporting machines

- Conductive pattern applied metal/ceramic parts

Cladding

Clad Roll

Clad roll is a product that formed functional film suitable for product purposes by cladding special materials on the exterior of the roll making use of diverse welding processes.

This is a product that fostered high strength materials on the surface to improve the hardness, abrasion-resistance and impact-resistance of the roll. This product exhibits outstanding performance under the environment of abrasion and extreme impact cause by transfer of high temperature products.

This is a product that fostered high strength materials on the surface to improve the hardness, abrasion-resistance and impact-resistance of the roll. This product exhibits outstanding performance under the environment of abrasion and extreme impact cause by transfer of high temperature products.

Main Features

- Outstanding combination performance due to melting of clad materials and parent materials

- Outstanding strength and abrasion resistance due to high hardness alloy material Clad

- Compact fostered layer of the Multi-Layer Clad make outstanding impact-resistance and corrosion-resistance

- Outstanding strength and abrasion resistance due to high hardness alloy material Clad

- Compact fostered layer of the Multi-Layer Clad make outstanding impact-resistance and corrosion-resistance

Applications

Steelworks : Hot-rolling thick plate table roll for transfer, down coiler roll, Guide roll

Cement : crusher roll, Kiln support roll, piston shaft etc.

Cement : crusher roll, Kiln support roll, piston shaft etc.

Clad Wear Plate, Crusher Roll

This is a product clad with hard metal complex powder with outstanding abrasion- resistance. This product substantially improved such problems as shrinkage deformation or distortion and the problem of characteristic breakdown caused by dilution.

As this product improves the tensile strength and impact strength of film through clad process control, this is increasingly applied to the parts of steelwork, cement and power plants which require abrasion-resistance and impact-resistance.

As this product improves the tensile strength and impact strength of film through clad process control, this is increasingly applied to the parts of steelwork, cement and power plants which require abrasion-resistance and impact-resistance.

Main Features

- Control of optimized carbide fraction for each use

- Outstanding abrasion-resistance due to alloy component dilution rate control

- Spalling minimization by applying internal stress relief technology

- Applicable to diverse purposes from abrasion-resistance to shock-resistance

- Outstanding abrasion-resistance due to alloy component dilution rate control

- Spalling minimization by applying internal stress relief technology

- Applicable to diverse purposes from abrasion-resistance to shock-resistance

Applications

Steelworks : Blast Furnace Distribution Chute, hosing Liner

Cement : Inlet shute, Wind leg duct, Transfer screw, Mixer etc.

Power Plant : Inlet shute, Feed pipe, Ventilator, Cyclone etc.

Paper Manufacture : Pump plunger, Calendar roll, Rotor disc etc.

Cement : Inlet shute, Wind leg duct, Transfer screw, Mixer etc.

Power Plant : Inlet shute, Feed pipe, Ventilator, Cyclone etc.

Paper Manufacture : Pump plunger, Calendar roll, Rotor disc etc.

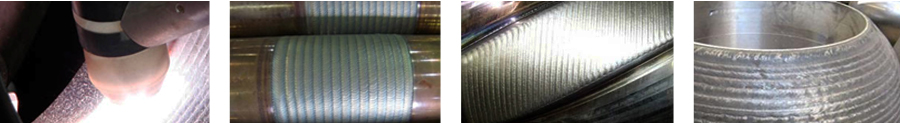

PTA

PTA (Plasma Transferred Arc) is a cladding technology that easily makes high stiffness abrasion-resistant film by using plasma heat source to nurture evenly the abrasion-resistant and corrosion-resistant special powder material over the product surface.

As the plasma-base technology easily nurtures high melting point material, this technology is increasingly applied to industries because of its adherence with the product, the outstanding property of no internal pore and flaw, and its high productivity.

As the plasma-base technology easily nurtures high melting point material, this technology is increasingly applied to industries because of its adherence with the product, the outstanding property of no internal pore and flaw, and its high productivity.

Main Features

- As a plasma heat source, there is no restriction of materials

- Outstanding combination performance due to melting of clad materials and parent materials

- Outstanding airtightness due to Defect-Free Clad layer

- Outstanding abrasion-resistance due to even distribution of carbide inside the thick film clad layer

- Outstanding combination performance due to melting of clad materials and parent materials

- Outstanding airtightness due to Defect-Free Clad layer

- Outstanding abrasion-resistance due to even distribution of carbide inside the thick film clad layer

Applications

Steelworks : Guide roll, Slitter, Tension reel, Cone block etc.

Petrochemistry : Ball valve, Turbine shaft, Shooting screw, Barrel, Flange etc.

Power Plant : Chute, Fan blade, Valve flange, Impeller etc.

Petrochemistry : Ball valve, Turbine shaft, Shooting screw, Barrel, Flange etc.

Power Plant : Chute, Fan blade, Valve flange, Impeller etc.

Clad Pipe & Fitting

Clad Pipe & Fitting is a product that formed superbly corrosion-resistant and abrasion- resistant film by applying various welding processes to the interior of Pipe and Fitting to improve the corrosion-resistance performance and lifetime substantially.

Clad Pipe and Fitting is a high added-value product that is mainly used for the pipe transferring petroleum produced in a deep sea or extremely cold place to the refining facility and for the pipe of petrochemistry refining facility.

Clad Pipe and Fitting is a high added-value product that is mainly used for the pipe transferring petroleum produced in a deep sea or extremely cold place to the refining facility and for the pipe of petrochemistry refining facility.

Main Features

- Outstanding combination performance due to melting of clad materials and parent materials

- Outstanding performance in low cost due to cultivation of functional film

- Flawless compact clad layer gives outstanding abrasion-resistance

- Outstanding corrosion resistance to corrosive gas

- Outstanding performance in low cost due to cultivation of functional film

- Flawless compact clad layer gives outstanding abrasion-resistance

- Outstanding corrosion resistance to corrosive gas

Applications

- Line pipe and fitting for transporting natural gas and petroleum

- Corrosive gas pipe in a petrochemistry facility

- Corrosive gas and dust particles pipe in a thermoelectric power plant

- Corrosive gas pipe in a petrochemistry facility

- Corrosive gas and dust particles pipe in a thermoelectric power plant